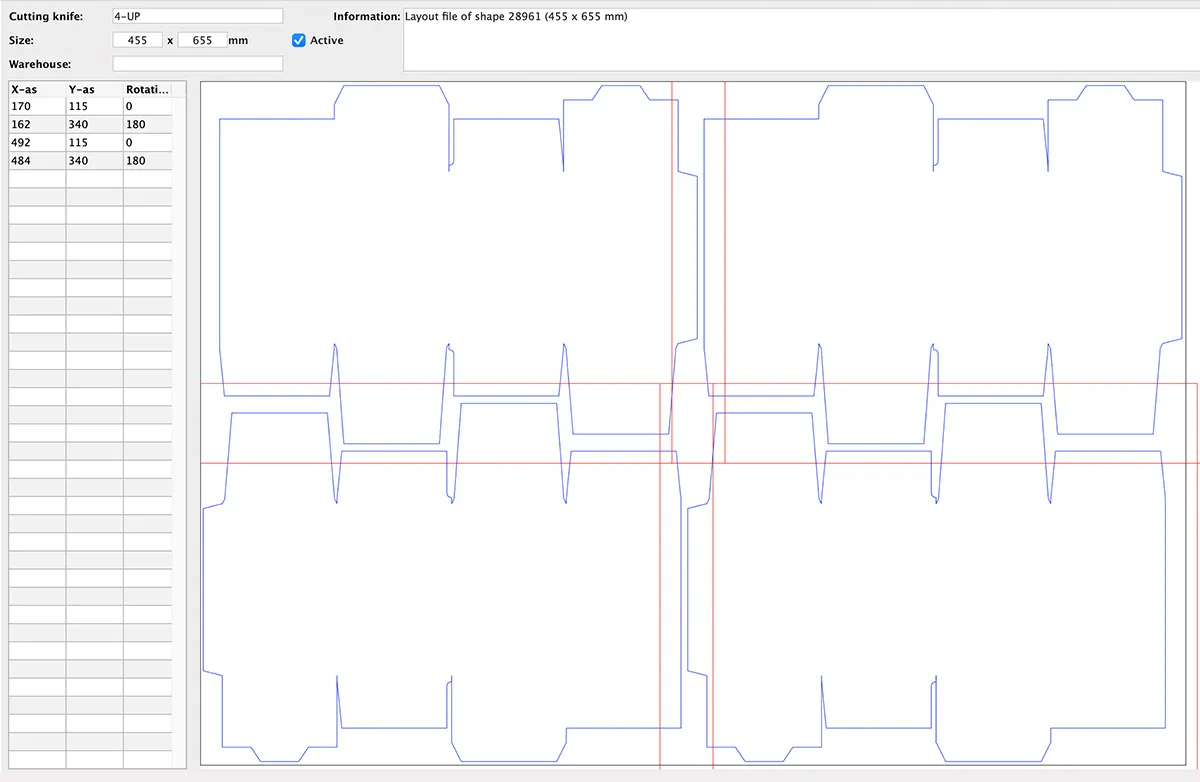

The optimal arrangement of your cutting frames in MultiPress

Many print companies face the same problem: in the imposition phase of the printing process, cutting frames always make it necessary to move away from a dynamic layout. For print products with an irregular shape - think of boxes or labels - it is quite a challenge to combine as many of these products as possible on one printing sheet. This clever combination is actually beneficial, because it means that fewer printing sheets are needed and the production time is reduced. There is also less material loss, which saves considerably on costs, especially for the often expensive substrates.

With this advanced calculation technique, you can describe your cutting frame library in MultiPress. This allows you to better prepare your imposition scheme for production and to easily calculate the price of special cuts for digital, offset and rotogravure printing.

With MultiPress you can easily calculate the cost and production times of your print job. The MultiPress calculation engine calculates the plates, the ink and the set-up times for each job. MultiPress takes into account the expected production speed (depending on the ink usage per printing form) and the required amount. When in doubt about the chosen printing press or layout, MultiPress will calculate the most economical combination and recalculate for all comparable combinations to achieve the most economical production cost.

- More orders in less time: automated combination of irregular forms (sometimes even from multiple jobs) on a printing sheet greatly simplifies the entire order flow, with fewer job changes and efficient production capacity

- Less material loss, lower costs: the production of combined orders requires fewer printing plates and reduces the amount of paper or substrate lost during order changes. All partial orders benefit from these advantages

- Sharper prices, better margins: the savings in time and costs allow for sharper offers or wider margins