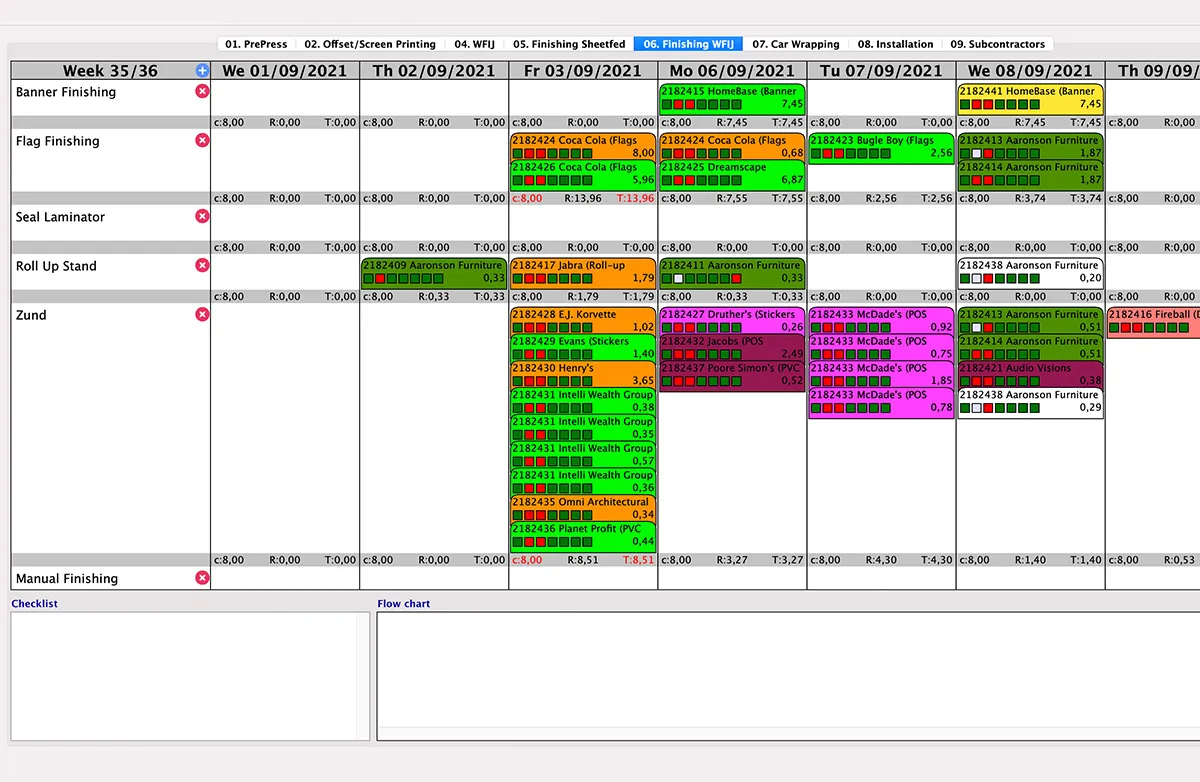

The MultiPress graphic planning board can optimally support you in your production planning for each order including finishing, handling and refinement processes. Despite the fact that planning the last steps in the production cycle is in many cases quite difficult and subject to the previous production steps, at MultiPress it was conceived very simply but ingeniously. The various operations are planned separately.

Is the print run complete? How should it be folded and cut, and what additional finishing is required? A good planning board makes the production planning in the finishing and refining department clear at a glance at any time. With the MultiPress graphic planning board, you always have direct access to the underlying order information.

The MultiPress graphic planning board provides a visual representation of the complete order flow during each stage of the production process. Using color coding, the status of an order and of the individual process steps is instantly visible.

All information of each individual order, machine and production employee is also easily and quickly accessible on the screen.

The sequence of each order can be flexibly adjusted, with MultiPress constantly monitoring the agreed planning and available capacity. In this way, everyone involved, whether the order manager, the planning department or the production staff, can immediately see whether an order is still in the prepress phase or already in the print shop, whether the files have already been received, the proof has been approved and the paper order has been delivered: all information is centrally available and always up-to-date.

- Overview and background: your production planning and all underlying order information are easily and quickly available

- Control and flexibility: the status of each order is always visible so that timely adjustments can be made

- Efficient production: with a clear and flexible planning board, your people work at an optimal pace according to production capacity

- On time and on schedule: MultiPress fully aligns the flow schedule of each order with your company's processes and capacity so that production and delivery take place on schedule.