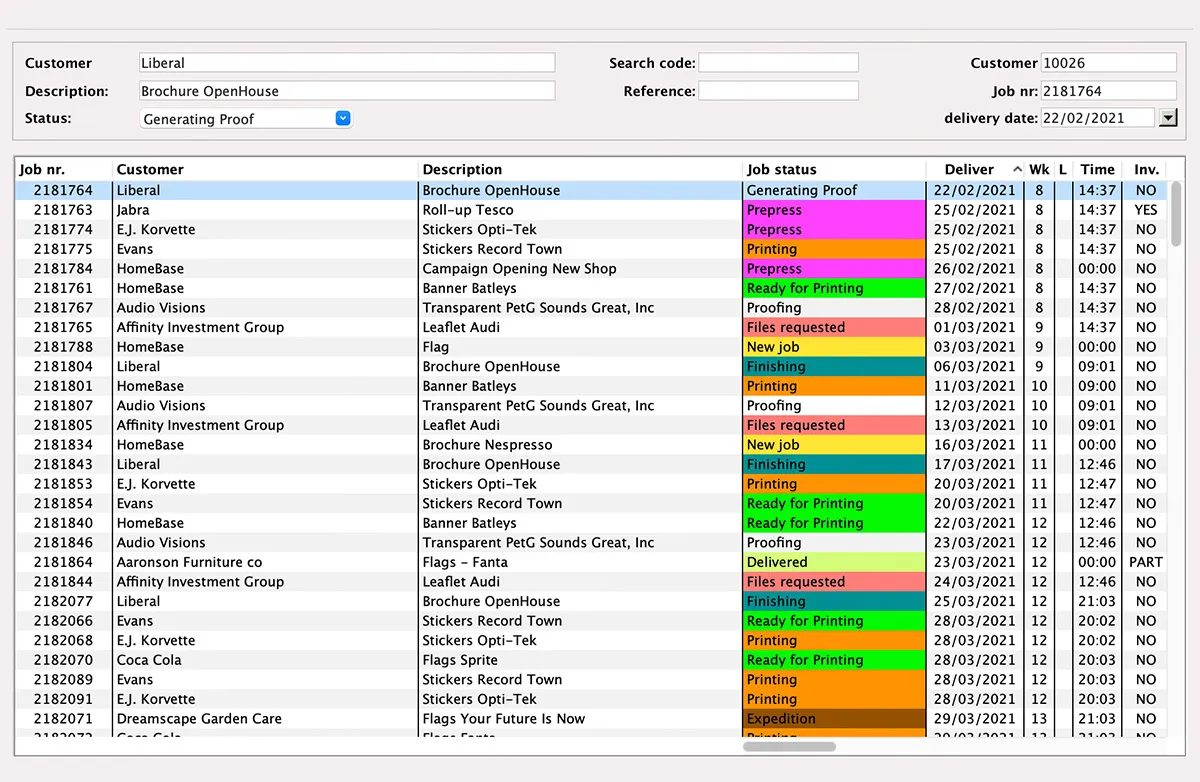

Quality Assurance in MultiPress provides an up-to-date overview of all orders and their individual status at any time. Progress control uses the same status color coding as in the graphic planning board so that the status is also instantly recognizable. In addition, it is easy to make specific selections, for example: of orders that are still waiting for file delivery or of all orders that are now in the print shop.

All the underlying information for each order is also immediately accessible. This information is managed centrally and is therefore always up to date. Where necessary, you can intervene directly and make adjustments to monitor progress. This guarantees optimal utilization of your production capacity and timely delivery of every order.

The MultiPress graphic planning board provides a visual representation of the complete order flow during each phase of the production process. The flow schedule of each order can be flexibly adjusted, with MultiPress always monitoring the agreed planning and available capacity.

Using color coding, the status of an order and of the individual process steps is immediately visible. All information for each individual order, machine and production employee can also be called up on the screen.

Overview and background: your production planning, from prepress and printing to finishing - including third-party work - and shipping, can be viewed at a glance, and all the underlying order information is available at the click of a mouse.

Control and flexibility: the status and progress of each order is always directly visible so that timely adjustments can be made

On time and on schedule: MultiPress saves you a lot of time in progress control and ensures that production and delivery take place on schedule